Process of Stainless Steel Seamless Pipe

Process is the soul of production. Good or bad product can be judged by the appearance. How do we do to escape the defect?

Process of Stainless Steel Seamless Pipe Description

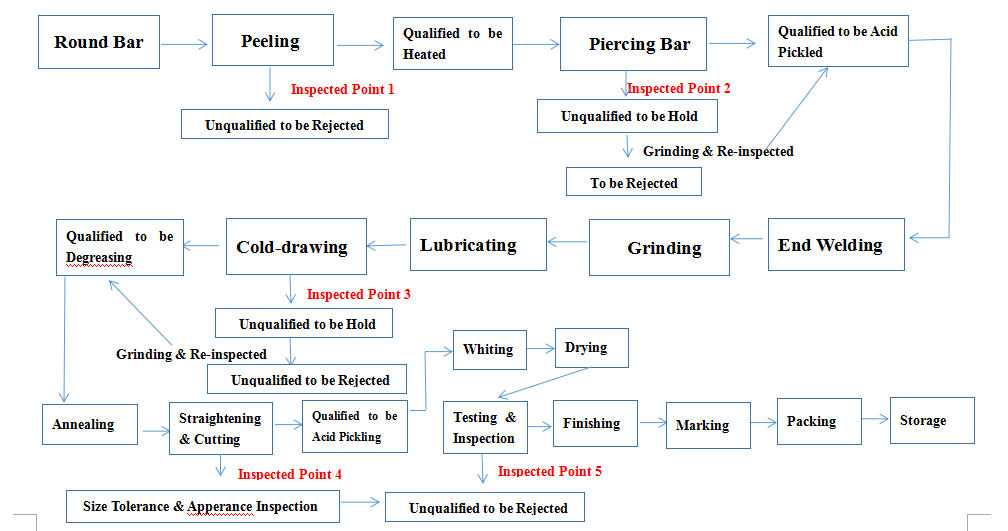

As we can see the production line below:

The first process when piercing bar come to the plant,we will inspect one by one. Pickled for the qualified pipe. Grinded for the unqualified pipe.

The point for this process is inspection which need the carefulness. Or any small crack will be enlarged on next process.

The point of pickling for qualified pipe is the solution. Because we need to remove the oxide skin. If the pipes are not clean, the oxide skin will be mushed into the body of pipes when we cold-working. They will be the hidden defect.

After that, the pipes will be seperately made head.

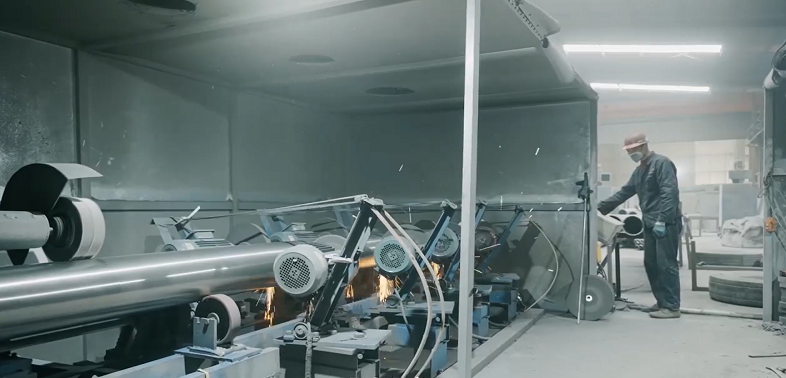

Now, we can grind to remove the small crack during course of piercing.

Then, the pipes will be lubricated.

After dried, they will be cold-drawing or cold-rolling according to the process requirements.

After that, all the pipes will go pickling to remove the butter and other elements.

Then, they will be annealed to remove the stress during course of cold-working.

The stable temperature is the point the pipes can get good physical properties. We have five points of temperature measurement.

After the pipes were cold and we will straighten them.

Repeat some processes, till the pipes were finished to cut. Then leave the samples to do Mechanical Properties and Chemical composition.

Thank you for your time.

Related Stainless steel seamless tube

Piercing Bar-The first step of quality control

Small crack are offen ignored. In order to improve the appearance quality, we need to do fully grinding for piercing ba...

Process of Stainless Steel Seamless Pipe

Process is the soul of production. Good or bad product can be judged by the appearance. How do we do to escape the defe...

Analysison Straightening Seamless Steel Pipe

The straightening process is generally used to eliminate the longitudinal bending and the roundness error of the rolled s...

Improved Pipe Appearance, Enlarged the Market

Inner beauty need to show by outer surface. The improving of pipe appearance is the kep step to prolong service time....

TP904L/UNS N08904

TP904L is a low carbon, high alloying austenitic stainless steel material designed for harsh corrosion conditions. It has...

UN S31803/ UN S32205 Duplex Stainless Steel Pipe

Austenitic-ferritic Duplex stainless steel pipe roughly has the same proportion both austenite and ferrite phase. Austeni...